Right-Angle Bevel Gearboxes

ATLANTA Drive Systems, Inc. has a complete range of Right-Angle Bevel Gearboxes available for continuous applications for power transmission. Light, medium and heavy duty reducers are available, with spiral-bevel gears and ratios from 1:1 to 5:1.

Typical applications for these reducers include rotary axis drives, conveyors, packaging equipment and typical drivetrains. Industries served include Material Handling, Automation and Packaging.

- Light Duty

Product Range - Medium Duty

Product Range - Heavy Duty

Product Range - Mounting and

Lubrication

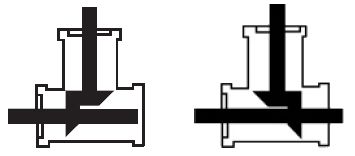

Light Duty Version: Ratios 1:1 to 1:3, Two and Three Shafts

| Part Number |

Ratio | Shafts | Rotation** | Torque Rating for Input Speed (lb.ft.)* | |||

|---|---|---|---|---|---|---|---|

| 125 rpm | 500 rpm | 1,000 rpm | 1,500 rpm | ||||

| 52.03.081 | 1:1 | 2 | LH/RH | 2.2 | 2.0 | 1.8 | 1.7 |

| 52.53.081 | 1:1 | 2 | RH/RH | 2.2 | 2.0 | 1.8 | 1.7 |

| 52.23.081 | 1:1 | 3 | --- | 2.2 | 2.0 | 1.8 | 1.7 |

| 52.03.141 | 1:1 | 2 | LH/RH | 9.5 | 8.4 | 7.3 | 7.1 |

| 52.53.141 | 1:1 | 2 | RH/RH | 9.5 | 8.4 | 7.3 | 7.1 |

| 52.23.141 | 1:1 | 3 | --- | 9.5 | 8.4 | 7.3 | 7.1 |

| 52.03.191 | 1:1 | 2 | LH/RH | 27.3 | 21.4 | 18.4 | 15.4 |

| 52.53.191 | 1:1 | 2 | RH/RH | 27.3 | 21.4 | 18.4 | 15.4 |

| 52.23.191 | 1:1 | 3 | --- | 27.3 | 21.4 | 18.4 | 15.4 |

| 52.03.241 | 1:1 | 2 | LH/RH | 37.6 | 30.2 | 25.8 | 22.1 |

| 52.53.241 | 1:1 | 2 | RH/RH | 37.6 | 30.2 | 25.8 | 22.1 |

| 52.23.241 | 1:1 | 3 | --- | 37.6 | 30.2 | 25.8 | 22.1 |

| Part Number |

Ratio | Shafts | Rotation** | Torque Rating for Input Speed (lb.ft.)* | |||

|---|---|---|---|---|---|---|---|

| 125 rpm | 500 rpm | 1,000 rpm | 1,500 rpm | ||||

| 52.05.081 | 1:2 | 2 | LH/RH | 0.9 | 0.9 | 0.9 | 0.9 |

| 52.55.081 | 1:2 | 2 | RH/RH | 0.9 | 0.9 | 0.9 | 0.9 |

| 52.25.081 | 1:2 | 3 | --- | 0.9 | 0.9 | 0.9 | 0.9 |

| 52.05.141 | 1:2 | 2 | LH/RH | 4.8 | 4.2 | 3.6 | 3.5 |

| 52.55.141 | 1:2 | 2 | RH/RH | 4.8 | 4.2 | 3.6 | 3.5 |

| 52.25.141 | 1:2 | 3 | --- | 4.8 | 4.2 | 3.6 | 3.5 |

| 52.05.191 | 1:2 | 2 | LH/RH | 14.7 | 9.6 | 8.1 | 7.3 |

| 52.55.191 | 1:2 | 2 | RH/RH | 14.7 | 9.6 | 8.1 | 7.3 |

| 52.25.191 | 1:2 | 3 | --- | 14.7 | 9.6 | 8.1 | 7.3 |

| 52.05.241 | 1:2 | 2 | LH/RH | 21.4 | 14.7 | 12.1 | 10.7 |

| 52.55.241 | 1:2 | 2 | RH/RH | 21.4 | 14.7 | 12.1 | 10.7 |

| 52.25.241 | 1:2 | 3 | --- | 21.4 | 14.7 | 12.1 | 10.7 |

| Part Number |

Ratio | Shafts | Rotation** | Torque Rating for Input Speed (lb.ft.)* | |||

|---|---|---|---|---|---|---|---|

| 125 rpm | 500 rpm | 1,000 rpm | 1,500 rpm | ||||

| 52.07.141 | 1:3 | 2 | LH/RH | 2.1 | 2.0 | 1.8 | 1.6 |

| 52.57.141 | 1:3 | 2 | RH/RH | 2.1 | 2.0 | 1.8 | 1.6 |

| 52.27.141 | 1:3 | 3 | --- | 2.1 | 2.0 | 1.8 | 1.6 |

| 52.07.191 | 1:3 | 2 | LH/RH | 6.4 | 5.1 | 4.2 | 3.4 |

| 52.57.191 | 1:3 | 2 | RH/RH | 6.4 | 5.1 | 4.2 | 3.4 |

| 52.27.191 | 1:3 | 3 | --- | 6.4 | 5.1 | 4.2 | 3.4 |

| 52.07.241 | 1:3 | 2 | LH/RH | 8.5 | 7.3 | 5.7 | 4.8 |

| 52.57.241 | 1:3 | 2 | RH/RH | 8.5 | 7.3 | 5.7 | 4.8 |

| 52.27.241 | 1:3 | 3 | --- | 8.5 | 7.3 | 5.7 | 4.8 |

*For reducers with three shafts, the torque given is the total torque.

**LH/RH - the shafts rotate the opposite direction, RH/RH - the shafts rotate the same direction.

Medium Duty Version: Ratio 1:1, Two and Three Shafts

| Part Number |

Shafts | Rotation** | Torque Rating for Input Speed (lb.ft.)* | |||

|---|---|---|---|---|---|---|

| 50 rpm | 500 rpm | 1,500 rpm | 3,000 rpm | |||

| 50.70.003 | 2 | LH/RH | 6.6 | 5.9 | 4.4 | 3.0 |

| 50.70.004 | 2 | LH/RH | 13.3 | 11.0 | 8.1 | 7.3 |

| 50.70.005 | 2 | LH/RH | 36.9 | 29.5 | 23.6 | 19.9 |

| 50.70.006 | 2 | LH/RH | 96 | 85 | 60 | 49 |

| 50.90.003 | 2 | RH/RH | 6.6 | 5.9 | 4.4 | 3.0 |

| 50.90.004 | 2 | RH/RH | 13.3 | 11.0 | 8.1 | 7.3 |

| 50.90.005 | 2 | RH/RH | 36.9 | 29.5 | 23.6 | 19.9 |

| 50.90.006 | 2 | RH/RH | 96 | 85 | 60 | 49 |

| 50.80.003 | 3 | --- | 6.6 | 5.9 | 4.4 | 3.0 |

| 50.80.004 | 3 | --- | 13.3 | 11.0 | 8.1 | 7.3 |

| 50.80.005 | 3 | --- | 36.9 | 29.5 | 23.6 | 19.9 |

| 50.80.006 | 3 | --- | 96 | 85 | 60 | 49 |

*For reducers with three shafts, the torque given is the total torque.

**LH/RH - the shafts rotate the opposite direction, RH/RH - the shafts rotate the same direction.

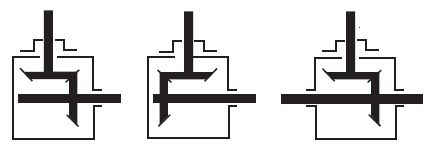

Heavy Duty Version: Ratios 1:1 to 1:5, Three Shafts

| Part Number |

Ratio | Thermal Rating (HP)* | Torque Rating for Input Speed (lb.ft.) | ||||

|---|---|---|---|---|---|---|---|

| 125 rpm | 500 rpm | 1,000 rpm | 1,500 rpm | 3,000 rpm | |||

| 53.23.003 | 1:1 | 5.36 | 36.9 | 29.5 | 23.6 | 20.6 | 14.7 |

| 53.23.004 | 1:1 | 9.3 | 103 | 73.7 | 59 | 51.6 | 36.8 |

| 53.23.005 | 1:1 | 13.4 | 177 | 140 | 110 | 106 | 70 |

| 53.23.006 | 1:1 | 20.7 | 295 | 236 | 184 | 162 | 125 |

| 53.24.003 | 1:1.5 | 5.36 | 25 | 22.8 | 20.6 | 19.2 | 14.7 |

| 53.24.004 | 1:1.5 | 9.3 | 70 | 65.6 | 59.7 | 55.3 | 43.5 |

| 53.24.005 | 1:1.5 | 13.4 | 129 | 118 | 103 | 95.8 | 73.7 |

| 53.25.003 | 1:2 | 5.36 | 25 | 22.8 | 20.6 | 19.2 | 14.7 |

| 53.25.004 | 1:2 | 9.3 | 70 | 65.6 | 59.7 | 55.3 | 43.5 |

| 53.25.005 | 1:2 | 13.4 | 129 | 118 | 103 | 95.8 | 73.7 |

| 53.27.004 | 1:3 | 9.3 | 70 | 65.6 | 59.7 | 55.3 | 43.5 |

| 53.27.005 | 1:3 | 13.4 | 129 | 118 | 103 | 95.8 | 73.7 |

| 53.31.004 | 1:5 | 9.3 | 54.5 | 50.1 | 45.7 | 42.7 | 31.7 |

*For continuous operating temperature of 176 deg. F.

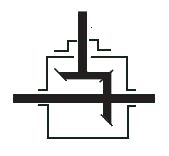

The housings are completely sealed and allow for mounting in any position. All reducers are run-tested and supplied filled with oil (except reducers with 8 mm shafts which use grease). For oil-level inspection, a removable sight gauge is provided which can be relocated as needed, depending on the mounting orientation. For the light-duty version, the plug screw serves as an oil level and filler plug.

Under normal operating conditions, the gear reducers are maintenance free. In the case of continuous running in the upper power range, the recommended oil change interval is every 2,000 hours of operation. In the case of low peripheral speeds, the gear reducers can be filled with grease up to the sight gauge location.