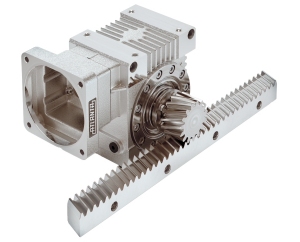

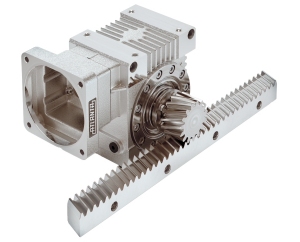

Medium-Precision Rack & Pinion Drive Systems

These systems utilize our our precision Planetary and Servo-Worm Reducers, to rigidly support and drive a hardened & ground pinion. The rack used in these systems is Quenched & Tempered, which has a quality level of DIN 8 (~AGMA 10) and through-hardened teeth.

These drives are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers and material handling systems. Medium loads and duty cycles can be easily handled with these drives.

Our Automatic Lubrication Systems are highly recommended for use with these drives, providing continuous grease lubrication to the rack & pinion tooth flanks to preserve the quality and lifetime of the gearing.

- System Precision

- Right-Angle System

Specifications - In-Line System

Specifications

The system precision, including the pitch error and backlash, can be found below:

| System Precision Level: |

Rack Type & Class: | Rack Quality Level: |

Rack Pitch Error: | Rack & Pinion Minimum Backlash: * |

|---|---|---|---|---|

| Medium | Quenched & Tempered (PR) |

DIN 8 (~AGMA 10) |

< 0.100 mm per meter |

0.04 mm |

*The rack and pinion backlash depends on the alignment of the rack to the linear guides.

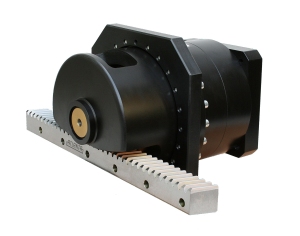

Our right-angle systems utilize our High-Torque (HT), High-Performance (HP) and Economy (E) Servo-Worm Reducers, which have backlash levels down to one arc-minute, to support and drive a hardened & ground pinion shaft. These reducers are available in six sizes and have ratios from 4.75:1 to 52:1 (higher ratios available with planetary-worm reducers). These reducers have options for keyed, compression or flanged outputs, which rigidly support our pinion.

The maximum drive force that each system can handle (with safety factor 1.0) is listed below; this should be compared to the application peak force, which can be calculated here, or by filling out our Application Sheet.

Please click on the table values for PDF specifications:

| Reducer Size: |

Rack & Pinion Module: |

Pinion Shaft: |

# of Pinion Teeth: |

Maximum Drive Force:* |

Maximum Linear Speed: |

|---|---|---|---|---|---|

| E Size 1 | 2 | 20.89.115 | 15 | 254 lb. | 4,144 in/min |

| HP Size 3 | 2 | 20.89.020 | 20 | 795 lb. | 4,144 in/min |

| 2 | 20.89.330 | 30 | 530 lb. | 8,288 in/min | |

| 3 | 20.89.320 | 20 | 530 lb. | 8,288 in/min | |

| HT Size 3 | 2 | 20.89.430 | 30 | 791 lb. | 8,288 in/min |

| 3 | 20.89.420 | 20 | 791 lb. | 8,288 in/min | |

| 4 | 20.89.415 | 15 | 791 lb. | 8,288 in/min | |

| HP Size 4 | 2 | 20.89.430 | 30 | 1,124 lb. | 6,631 in/min |

| 3 | 20.89.420 | 20 | 1,124 lb. | 6,631 in/min | |

| 4 | 20.89.415 | 15 | 1,124 lb. | 6,631 in/min | |

| HT Size 4 | 2 | 20.89.530 | 30 | 1,342 lb. | 6,631 in/min |

| 3 | 20.89.520 | 20 | 1,483 lb. | 6,631 in/min | |

| 4 | 20.89.515 | 15 | 2,062 lb. | 6,631 in/min | |

| HP Size 5 | 2 | 20.89.530 | 30 | 1,342 lb. | 4,973 in/min |

| 3 | 20.89.520 | 20 | 1,483 lb. | 4,973 in/min | |

| 4 | 20.89.515 | 15 | 1,888 lb. | 4,973 in/min | |

| HT Size 5 | 4 | 20.89.615 | 15 | 2,119 lb. | 4,973 in/min |

| 4 | 20.89.630 | 30 | 2,225 lb. | 9,946 in/min | |

| 5 | 20.89.612 | 12 | 2,190 lb. | 4,973 in/min | |

| HP Size 6 | 4 | 20.89.615 | 15 | 2,119 lb. | 4,973 in/min |

| 4 | 20.89.630 | 30 | 2,248 lb. | 9,946 in/min | |

| 5 | 20.89.612 | 12 | 2,190 lb. | 4,973 in/min | |

| HT Size 6 | 5 | 20.89.715 | 15 | 3,334 lb. | 6,216 in/min |

| HP Size 7 | 5 | 20.89.715 | 15 | 3,334 lb. | 4,083 in/min |

*Force ratings do not include any safety factors. Drive forces vary depending on gearbox ratio selected.

Our ZTR & ZR Rack & Pinion Drive Systems utilize our Precision Planetary Reducers with an ISO 9409-1 output flange to provide a rigid support for a hardened & ground helical pinion. This provides tight integration of the driven load while allowing replacement of the pinion if needed. These systems are available in seven sizes with backlash levels down to one arc-minute and ratios from 4:1 to 100:1.

The maximum drive force that each system can handle (with safety factor 1.0) is listed below; this should be compared to the application peak force, which can be calculated here, or by filling out our Application Sheet.

Please click on the table values for PDF specifications:

| Reducer Size: |

Rack & Pinion Module: |

Pinion: |

# of Pinion Teeth: |

Maximum Drive Force:* |

Maximum Linear Speed with 3,000 rpm Motor: |

|---|---|---|---|---|---|

| 3 | 2 | 78.20.526 | 26 | 495 lb. | 5,118 in/min |

| 2 | 78.20.527 | 27 | 495 lb. | 5,315 in/min | |

| 2 | 78.20.529 | 29 | 475 lb. | 5,709 in/min | |

| 2 | 78.20.535 | 35 | 394 lb. | 6,890 in/min | |

| 4 | 2 | 78.21.912 | 12 | 459 lb. | 2,362 in/min |

| 2 | 78.21.916 | 16 | 715 lb. | 3,150 in/min | |

| 2 | 78.21.533 | 33 | 835 lb. | 6,496 in/min | |

| 2 | 78.20.536 | 36 | 765 lb. | 7,087 in/min | |

| 2 | 78.21.537 | 37 | 744 lb. | 7,283 in/min | |

| 5 | 2 | 78.22.912 | 12 | 459 lb. | 787 in/min |

| 2 | 78.22.919 | 19 | 859 lb. | 1,247 in/min | |

| 2 | 78.22.923 | 23 | 1,013 lb. | 1,509 in/min | |

| 2 | 78.22.540 | 40 | 1,686 lb. | 2,625 in/min | |

| 2 | 78.22.545 | 45 | 1,507 lb. | 2,953 in/min | |

| 3 | 78.32.912 | 12 | 730 lb. | 1,181 in/min | |

| 3 | 78.32.912 | 14 | 1,009 lb. | 1,378 in/min | |

| 3 | 78.30.530 | 30 | 1,507 lb. | 2,953 in/min | |

| 7 | 2 | 78.23.923 | 12 | 459 lb. | 787 in/min |

| 2 | 78.23.923 | 23 | 1,013 lb. | 1,509 in/min | |

| 2 | 78.23.929 | 29 | 1,315 lb. | 1,903 in/min | |

| 3 | 78.33.912 | 12 | 730 lb. | 1,181 in/min | |

| 3 | 78.33.916 | 16 | 1,148 lb. | 1,575 in/min | |

| 3 | 78.33.919 | 19 | 1,413 lb. | 1,870 in/min | |

| 3 | 78.33.535 | 35 | 2,744 lb. | 3,445 in/min | |

| 3 | 78.33.540 | 40 | 2,472 lb. | 3,937 in/min | |

| 4 | 78.43.912 | 12 | 1,324 lb. | 1,575 in/min | |

| 4 | 78.40.530 | 30 | 2,472 lb. | 3,937 in/min | |

| 8 | 3 | 78.34.912 | 12 | 730 lb. | 1,181 in/min |

| 3 | 78.34.919 | 19 | 1,413 lb. | 1,870 in/min | |

| 3 | 78.34.926 | 26 | 2,010 lb. | 2,559 in/min | |

| 3 | 78.34.932 | 32 | 2,516 lb. | 3,150 in/min | |

| 4 | 78.44.912 | 12 | 1.324 lb. | 1,575 in/min | |

| 4 | 78.44.917 | 17 | 2,430 lb. | 2,231 in/min | |

| 4 | 78.44.919 | 19 | 2,732 lb. | 2,493 in/min | |

| 4 | 78.44.520 | 20 | 2,913 lb. | 2,625 in/min | |

| 5 | 78.44.512 | 12 | 2,190 lb. | 1,969 in/min | |

| 5 | 78.44.516 | 16 | 3,602 lb. | 2,625 in/min | |

| 5 | 78.54.918 | 18 | 4,049 lb. | 2,953 in/min | |

| 9 | |||||

| 4 | 78.46.912 | 12 | 1,324 lb. | 1,575 in/min | |

| 4 | 78.46.919 | 19 | 2,732 lb. | 2,493 in/min | |

| 4 | 78.46.920 | 20 | 2,913 lb. | 2,625 in/min | |

| 5 | 78.56.914 | 14 | 2,906 lb. | 2,297 in/min | |

| 5 | 78.56.918 | 18 | 4,049 lb. | 2,953 in/min | |

| 5 | 78.56.919 | 19 | 4,327 lb. | 3,117 in/min | |

| 5 | 78.56.920 | 20 | 4,238 lb. | 3,281 in/min | |

| 10 | |||||

| 5 | 78.57.912 | 12 | 2,190 lb. | 1,969 in/min | |

| 5 | 78.57.919 | 19 | 4,327 lb. | 3,117 in/min |

*Force ratings do not include any safety factors. Higher forces are possible depending on gearbox ratio selected.

HighForce Precision Planetary Rack & Pinion Drive Systems

HighForce Precision Planetary Rack & Pinion Drive Systems