Whitepapers

We have many whitepapers available on our various products, please see below.

Separating Rack & Pinion Myths From Reality

Separating Rack & Pinion Myths From Reality

Rack and pinion drives are an age-old mechanism widely used for converting rotary motion to linear motion. However, myths and misconceptions abound regarding the use and application of rack & pinions in this age of servo-driven machinery.

Choosing The Right Rack & Pinion

Rack and pinions are one of the oldest and simplest mechanisms used for converting rotary motion into linear motion. They are extremely versatile and can be used in a wide range of applications, from simple, hand operated machinery to highly dynamic, ultra-precise machine tool applications.

Optimizing Gear Rack Assembly

The positioning accuracy of a rack & pinion drive is dependent on the cumulative pitch error inherent in each gear rack used. For long travel lengths, this cumulative pitch error can add up very quickly and dramatically affect the positioning accuracy of the axis.

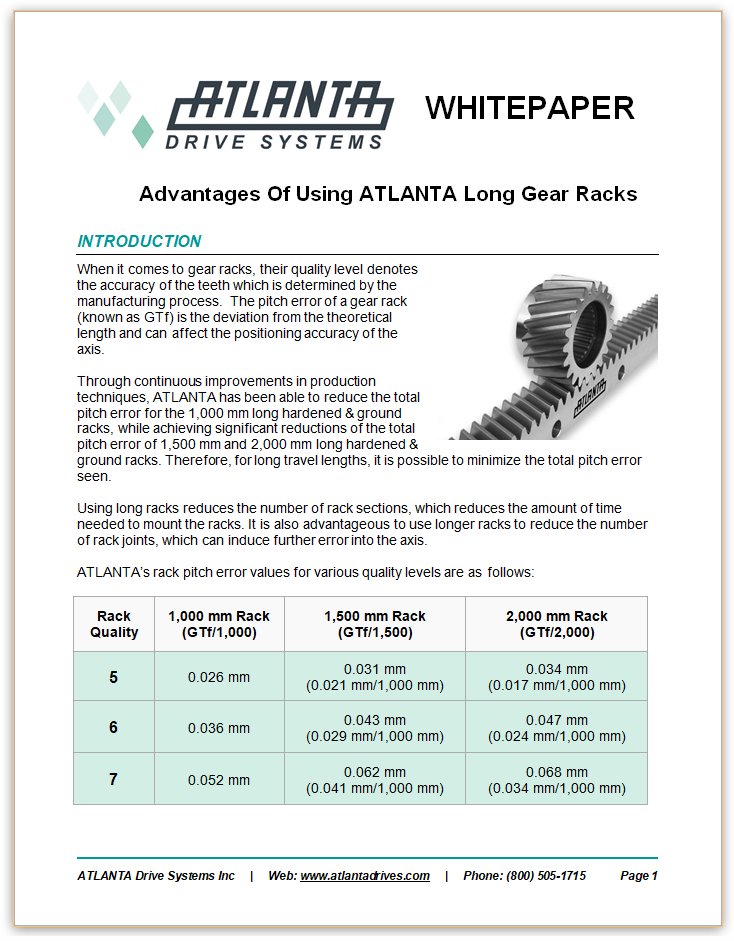

Advantages Of Using ATLANTA Long Gear Racks

Using long racks reduces the number of rack sections, which reduces the amount of time needed to mount the racks. It is also advantageous to use longer racks to reduce the number of rack joints, which can induce further error into the axis.

Advantages of Using ATLANTA Small Pinions

When it comes to selecting a pinion for use in a rack & pinion drive system, the pinion pitch diameter can have a huge effect on the system. ATLANTA has a wide range of pinions, including ISO flanged pinions, which gives the design engineer flexibility to optimize his design.

Worm Gearhead Handles Servo Demands

Servo applications often impose severe demands on drive components, thereby ruling out the use of many geared speed reducers. However, advanced worm gearhead designs are changing this picture.

To receive a whitepaper by email, please fill out all of the fields below and then press [Send Request].